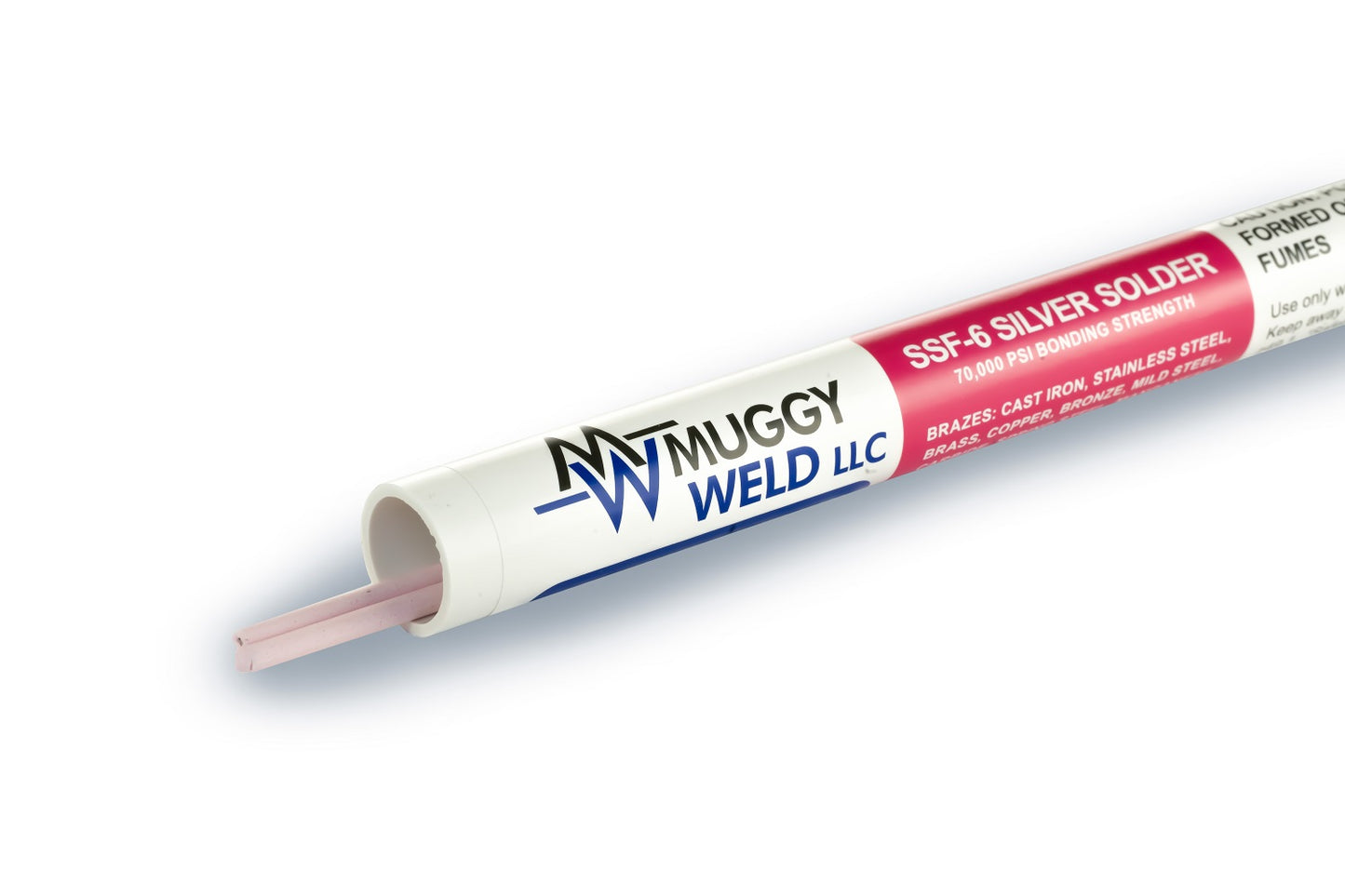

SSF-6 56% Silver Solder

SSF-6 56% Silver Solder

SSF-6 is high-strength 56% silver solder rod. An ideal replacement for fluxless silver solder coils, our flux-coated rod has high thin flow, flows easily, and can be used with a variety of metals at over 70,000 psi.

SSF-6 is the only fluxed silver solder that’s strong enough to clean oxidized stainless steel, and wets even burned stainless. It can be used to braze cast iron, and to bond stainless steel, brass, copper, bronze, mild steel, carbide, carbon steel, spring steel, manganese steel, chrome-moly, carbon-moly, galvanized iron, cadmium coated steel, German steel, inconel , cupronickel, silicone bronze, silver, gold, and cast steel individually or with other metals. To ensure safe use for medical and pharmaceutical applications, our product is also cadmium-free.

Key Features:

- Silver solder possesses tensile strength up to 70,000 PSI

- Absorbs contraction and heat shock during rapid cooling

- Specially formulated flux coating provides twice the base metal cleansing action of conventional silver flux coatings

- Cadmium free formula is ideal for restaurant and pharmaceutical applications

- Highly active flux coating, promoting excellent bonding

- Perfect color match to stainless steel

- Can braze cast iron exhaust manifolds

- The rod of choice for air conditioning applications (HVAC), copper plumbing, automotive, hospital, restaurant, gun repair and jewelry-making

- Helps produce leak-tight, smooth, electrically conductive and corrosion-resistant joints

- Strong enough to clean oxidized stainless steel, wets even burnt stainless steel

- 1 inch of material can flow 18 inches on thin tight-fitting metals, bonding even hard to reach areas

- Flows in all positions at 1150°F

- Extended shelf life: product will retain usability for years if stored in original packaging

- Easy clean-up with warm water and a wire brush

- Corrosion resistant

- Simple to use: apply flux-coated rod when the parent metal reaches a dull red

Note: Pre-cleaning the parent metal is always advised, as it will result in a stronger bond.

Your torch must be able to heat the metal to 1150°F to flow properly. Large pieces or thick metal may require oxyacetylene to achieve proper working temperature.

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share